magnetic separation process flow diagram

The simplified flowsheet of magnetic separation

Download scientific diagram The simplified flowsheet of magnetic separation process: dry low-intensity magnetic separation (LIMS) and high-intensity magnetic separation (HIMS). from...

More

Magnetic Separation - an overview ScienceDirect Topics

3.11.2.5 Magnetic Separation. Magnetic separation is a process where a contaminant is first attached onto a magnetic carrier material (e.g., magnetite), and subsequently, the

More

Magnetic Separation Process SpringerLink

2023.6.22 Therefore, an appropriate magnetic separation process needs to be combined with the research results of process mineralogy and determined through

More

Block flow diagram and illustration of a batch

Magnetophoresis of MNPs can be further divided into two classes: high gradient magnetic... Magnetic Nanoparticles, Divorce and Gradient ResearchGate, the professional network for scientists.

More

Working principle and application of magnetic

2016.12.6 Figure 2. ( a) Schematic diagram showing the principle of i-RBC separation from a blood sample using a microfluidic device

More

Flow chart of magnetic separation process for wastewater

Download scientific diagram Flow chart of magnetic separation process for wastewater treatment with magnetic adsorption (a and b express conventional and new magnetic

More

MAGNETIC SEPARATION - Springer

2017.8.29 The most important operational parameter characterizing the magnetic separation process is the magnetic force acting upon a particle. To derive an

More

Magnetic Separation SpringerLink

2022.2.28 A dry high-intensity magnetic separator is a waterless separation machine introduced to separate weakly magnetic particles that DLIMS cannot process. This

More

Magnetic separation: A review of principles, devices, and applications ...

The principle of operation of magnetic separation devices is the interaction between magnetic forces and competing gravitational, hydrodynamic, and interparticle forces

More

Magnetic Separation - an overview ScienceDirect Topics

Magnetic separation methods are widely used for isolation of a variety of cell types. Magnetic particles with immobilized antibodies to various antigens have been employed

More

The six main steps of iron ore processing - Multotec

6. Magnetic separation The concentrate collected from the middlings and tails after spiral gravity separation has a lower iron concentration (magnetite) so it must be further concentrated to achieve the customer’s 65% Fe concentration. It is immediately directed to a magnetic separator circuit. Magnetised drums collect magnetic material, so ...

More

Flow chart of separation process [59]. Download

Flow chart of separation process [59]. ... Mechanical treatments, magnetic separation, acid treatments, pyrometallurgical, hydrometallurgical, bio-metallurgical approaches are some of the ...

More

Process and Principle of Magnetic Separation of Iron Ore

2021.6.26 The weak magnetic separation process is mainly used to process strong magnetic minerals such as magnetite, and the strong magnetic separation process is mainly used to process weak magnetic minerals such as hematite. ... If you need equipment quotation and process flow, please feel free to Contact Us: Whatsapp: +8618026978087;

More

Working principle and application of magnetic separation

2016.12.6 Therefore, understanding the factors that simultaneously influence the efficiency of both magnetic separation process and target detection is necessary. Moreover, for LGMS, there are several important considerations that should be taken into account in order to ensure its successful implementation. ... Schematic diagram illustrating a free

More

Minerals Free Full-Text Separation Analysis of New Magnetic

2022.6.1 To achieve the utilization of fine ilmenite (especially −0.075 mm) produced in the titanium-magnetite processing plant in Panzhihua, a radial turbulent outer-cylinder magnetic separator (RTOCMS), was developed in this study. After optimizing the conditions of rotation speed and water flow, an RTOCMS concentrate with TiO2 grade of 22.84%

More

Magnetic Separation - an overview ScienceDirect Topics

Magnetic separation is an efficient separation technique in which CDs and iron oxide (Fe3 O 4) nanocrystals are utilized as doped material embedded in mesoporous silica beads. Silica microbeads are selected due to nano-sized pores, hydrophobic interactions with doped materials, and a large surface area.

More

High gradient magnetic separators Continuous HGMS

2018.8.29 The success of any magnetic separation process is governed by the property of the material to be collected and the structure of the separator to carry out the process. This can be expressed ... • Magnetic field adjustment • Flow of raw and closed loop water in the cooling system • Bearing lubrication system • Temperature in magnet coils

More

Superconducting Magnetic Separation SpringerLink

2023.4.13 Superconducting magnetic separation is a method of mineral separation by a magnetic separator with superconductor as a magnetic system. Its application is mainly with the aid of a superconducting magnetic separator equipment. Following the birth of the first superconducting magnet in 1961, J.D. Bannister of the United States invented the

More

How to Extract Iron from Hematite: Methods and Plants

2023.2.15 The process flow of the extraction of iron from hematite is as follows: crushing, grinding, extracting (flotation separation, magnetic separation, gravity separation, etc.) and drying. Stage I Crushing and screening hematite; Stage II Grinding hematite; Stage III Extracting iron from hematite *Hematite flotation separation *Hematite magnetic ...

More

Minerals Free Full-Text Dry Permanent Magnetic

2022.9.9 Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiency. These tools not only discard some amount of bulk gangue from the raw ore, thereby reducing the volume of the grinding operation and cutting energy consumption, but also

More

Magnetic Separation SpringerLink

2022.2.28 A dry high-intensity magnetic separator is a waterless separation machine introduced to separate weakly magnetic particles that DLIMS cannot process. This technology employs a greater magnetic field strength provided by an induced or permanent magnet to separate the materials based on their magnetic susceptibility [ 21 , 22 ].

More

IR1-3 Ore Processing

2021.5.18 possibility of adding in magnetic separation circuits to recover a low copper, high nickel/iron concentrate from the primary concentrate, as well as recover a magnetite concentrate from the tailings feed. The magnetic separation circuits are absent from the process flow diagram presented with the Feasibility Study.

More

Magnetic Separation Method - 911 Metallurgist

2015.6.24 Magnetic Separation Method. Magnetic separation is a process used to separate materials from those that are less or nonmagnetic. All materials have a response when placed in a magnetic field, although

More

Development of magnetic flotation hybrid separation process

2023.11.1 At a higher level of magnetic field strength, reducing the air flow rate to a value less than 800 ml/min negatively impacted the separation efficiency as shown in Fig. 6 (b), while the separation efficiency slightly decreased at both higher levels of air flow rate and magnetic field strength, but at a lower level of magnetic field strength ...

More

Influence of Separation Angle on the Dry Pneumatic Magnetic Separation

2022.8.18 Dry magnetic separation is a green mineral processing technology with lower production costs and minor environmental impact. It is a promising technique to separate fine-grained materials with high magnetic susceptibility, such as magnetite and smelting slags, especially in water-scarce areas [1,2].However, strong adhesion between

More

Magnetic Separation - an overview ScienceDirect Topics

Wastewater Treatment and Reuse. Y. Gong, D. Zhao, in Comprehensive Water Quality and Purification, 2014 3.11.2.5 Magnetic Separation. Magnetic separation is a process where a contaminant is first attached onto a magnetic carrier material (e.g., magnetite), and subsequently, the contaminant-laden carrier is separated under a magnetic field. The

More

Separation processes - processdesign - Northwestern

2016.2.22 The process would then be repeated for the indirect sequence, and the decision for which process to use would be justified by the process with the overall minimum vapor flow (Biegler et al., 1997). Absorption Description of Absorption. Another separation process used in industry is absorption, which is used to remove a solute from a gas stream.

More

Pulsation curves strengthen the high gradient magnetic separation ...

2022.5.31 The magnetic separation in the ilmenite process can effectively reduce gangue content, improve ilmenite grade, and provide high-quality flotation feeding. We use the x-ray diffraction analysis and laser particle size analysis to reveal the changes in mineral composite and particle size of concentrate prepared by different PHGMS operation ...

More

Magnetic cell separation - ScienceDirect

2022.1.1 The column-based MACS is a favored technique for separation of cells due to the high magnetic field gradient. The column-based MACS includes a column that is packed with randomly entangled magnetically susceptible wires [68] or ferromagnetic spheres [69] and it is surrounded by an electromagnet, Fig. 7.1A.After activating the

More

Magnetic Separation Process SpringerLink

2023.6.22 Magnetic Separation Process. Magnetic separation process is a combination and procedure for separating magnetic materials from non-magnetic materials by utilizing magnetic separation. In view of the difference in physical and chemical properties of the materials to be processed, the crystal sizes of the magnetic materials, the

More

Magnetic separations - ScienceDirect

2022.1.1 Magnetic separation plays an increasingly important role in analytical chemistry, nanotechnology, biochemistry, and molecular biology research methods, and further afield: in applied and condensed matter physics, physical chemistry, materials science, and industrial applications. It becomes especially important in biomedical

More

6 Magnetic Separation - Springer

2017.8.25 Magnetic separators have been used for almost 200 years for the concentration of magnetic ores and there has been a steady movement forward in both the equipment available and the range of materials for which magnetic separation is applicable. However, in all cases there are certain desirable design elements that must be applied

More

Developments in the physical separation of iron ore: magnetic ...

2015.1.1 Abstract. This chapter introduces the principle of how low-grade iron ores are upgraded to high-quality iron ore concentrates by magnetic separation. Magnetite is the most magnetic of all the naturally occurring minerals on earth, so low-intensity magnetic separators are used to upgrade magnetite ores. On the other hand, because oxidized

More

Separation and Recovery of Rare Earths and Iron from NdFeB Magnet

2023.9.30 NdFeB magnet scraps contain large amounts of iron, which poses challenges in recycling and greatly hinders the recovery of rare earths through direct hydrometallurgical treatment. To address this issue, we conducted tests using a flash furnace to explore the low-temperature reduction behavior of NdFeB magnet scraps

More

Magnetic separation using superconducting magnets

2001.8.1 Open gradient magnetic separation (OGMS) devices [30] were also developed for removal of heavy metals from laboratory discharge effluents. These devices use a Nb 3 Sn superconducting magnet and have no magnetic wire filters in the center, but have a zone of high magnetic forces that acts on particles.

More

Magnetic Separation: ProcessExamplesTypesApplication

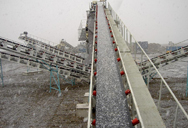

1 天前 5 Examples of Magnetic Separation: Magnetic drum separator: A drum-shaped magnet that separates ferrous material from non-magnetic material. It is commonly used in recycling, mining, and the steel industry to separate metal particles from waste material. Overband/Conveyor magnetic separator: A conveyor belt that contains a suspended

More

Minerals Free Full-Text Mathematical Model of Ilmenite Separation ...

2022.6.29 High gradient magnetic separation is widely used in magnetic minerals upgrading, and its separation performance is significant depending on the parameters. In this investigation, the Mathematical model of the plate high gradient magnetic separator is established, the magnetic induction and the flow field distribution are investigated based

More

OIL AND GAS SEPARATION PROCESS - NDT Inspect

2022.1.10 Figure 1: Oil and Gas 1 st Stage Separation Process flow Diagram (Simplified) Inlet temperature is often in the range of 100-150 degrees C. On the example platform, the well stream is colder due to Subsea wells and risers. The pressure is often reduced in several stages but commonly, three stages are used, and these allow

More

Preparation and Melting of Scrap in Aluminum Recycling: A Review

The magnetic separation is widely used for sorting UBCs, this process provides the most compact and efficient method of sorting aluminum and steel cans. In general, two cycles of magnetic separation are planned for cleaning UBC scrap. Furthermore, most municipal recycling facilities (MRFs) also feature magnetic separation in their process.

More