pulveriser mill coal power

Boiler Mill and Coal Pulverizer Performance GE Steam Power

5 天之前 Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full

More

Pulveriser Mill Performance Analysis Optimisation in

2018.9.24 The milling system is an important. part of the auxiliary equipment of a coal-fired power plant. Pulveriser mill are one of the critical equipment of coal. fired

More

Coal Pulverizers - an overview ScienceDirect Topics

In the first computational example the coal pulverizer drive system is considered. This machine is driven by the 22 kW asynchronous motor by means of the reduction planetary

More

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018.1.1 The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend

More

A Comparison of Three Types of Coal Pulverizers

2023.9.18 Mill Speed Capacity Desired Coal Properties Feed Size Total Moisture Grindability (HGI) Abrasiveness Prod. Fineness thru 200 Mesh Standard Screen Typical

More

Multiphase flow simulation of a simplified coal pulveriser

2005.7.25 1. Introduction Pulverisers play dominant role in dictating the performance and efficiency of combustion systems in power station boilers. Pulveriser is employed to

More

(PDF) Optimization and transformation of 300MV units steel ball coal ...

2019.11.7 The current system for thermal power system operation stability ball mill, poor uniformity of pulverized coal that often occurs overpressure, breaking coal, over

More

Improving Coal Pulverizer Performance and Reliability

2023.7.5 The four most common types of coal pulverizers are: Ball-Tube Mills This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced

More

Coal Pulverization System: Explosion Prevention and

2017.1.5 Explosion Prevention and Process Control. Abstract: A pulverized coal processing system for produc-ing coal powder used in aluminum alloy smelting process

More

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

5 天之前 The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter. Raw coal to be ground is fed from the ...

More

Industrial Coal Pulverizer Model Simulation and Parametric ...

2018.1.1 The coal-pulverizer is an important unit, which pre-processes coal-fuel fed to the boiler in coal-based thermal power plants. It is extremely important to comprehend the operational behavior of the coal pulverizer unit for good performance of the boiler and overall coal power-plant. This paper describes the first principle based energy and mass ...

More

Coal Pulverizer – Power Plant Pall Corporation

6 天之前 In order to protect the coal pulverizer lube system components, Pall recommends maintaining a fluid cleanliness level of ISO 16/13 or better. This can be accomplished through the use of Athalon AS grade (ß12 (c)≥

More

Multiphase flow simulation of a simplified coal pulveriser

2005.7.25 In coal-fired power plants, the first major component is pulveriser, whose performance dictates the total power station efficiency. ... Description of pulveriser. Coal pulverisers or mills grind coal typically from 10 to 50 mm size coal lumps to provide fine coal dust particles usually less than a micron up to several microns in size (with at ...

More

“Blueprint” Your Pulverizer for Improved Performance

2020.8.27 performance is governed by uniform coal combustion by the burn-ers and satisfactory coal fineness. Adequate fineness for both west-7. Optimum design. Ensure optimum arrangement of the mill throat and the coal flow path to improve mill performance. Source: Storm Technologies Inc. Grinding surface Finer particles and air to rise to

More

(PDF) Optimization and transformation of 300MV units steel ball coal ...

2019.11.7 Abstract and Figures. Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing system.At the same time,analyze the main operating parameters before ...

More

Pulverizer Plant OM Aspects

2013.12.6 Nomenclature-Bowl Mills 583 XRS / 803 XRP Bowl mills 58,80 stands for bowl diameter in inches If the number is even then its shallow bowl mill. If the number is odd then its deep bowl mill 3 - number of rollers three nos. X - frequency of power supply 50 cycles.In USA ’x’ means 60 cycles. R- Raymond, name of the inventor

More

Coal Mill - an overview ScienceDirect Topics

Observer-Based and Regression Model-Based Detection of Emerging Faults in Coal Mills. Peter Fogh Odgaard, ... Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007. 5.2 Experiments with and design of the regression model-based approach. Operating data from a coal mill is used to compare the fault detection

More

Boiler Mill and Coal Pulverizer Performance GE Steam Power

5 天之前 YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions. This is the Power of Yes.

More

Model predictive control for an industrial coal pulveriser ...

2021.9.6 The coal-pulveriser/coal-mill is an important subsystem upstream of boilers in coal-based thermal power plants. The efficient boiler operations demand optimum combustion-air to coal-fuel ratio (AFR). In fact, portion of (preheated) combustion-air called primary-air, passes through coal-mill and carries pulverised coal to the boiler. The safe,

More

Reliable Coal Pulverizers and Mills » Babcock Wilcox

Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. BW's pulverizers, found at power stations throughout the world.

More

An investigation of performance characteristics

2020.8.12 In a coal-fired power plant, one of the main equipment is the coal mill, whose effectiveness influences mainly the whole power plant performance (Shah, Vuthaluru, and Vuthaluru 2009 ).

More

IN THE AUSTRALIAN COMPETITION TRIBUNAL AGL

2019.4.29 Energy Conversion Process –Coal to Electricity The key element of the pulverised fuel system is the coal pulveriser (mill). The purpose of the pulverisers is the comminution (size reduction) of incoming coal from a top size of between typically 50 and 75 mm down to 75 microns (µm).

More

Coal pulverisation with vertical roller mills Engineer Live

2013.2.1 Within the power industry, vertical roller mills (VRMs) are the predominant equipment used for coal pulverisation. The essential requirements of pulverisation are grinding, heating, classification and transport of the pulverised coal from the pulveriser. The grinding elements coupled with proper alignment and compression are critical to coal ...

More

ISSN (Print) : 0973-0338 Central Power Research Institute

Section of coal bowl mill. Table 1. Guaranteed coal conditions for mill performance evaluation Coal Moisture % 20 Coal HGI 55 Mill Outlet Temperarure °C 80 Mill Air Flow T/hr. 102 Coal Fineness (% passing trough 200 mesh) 70% passing through 200 mesh and 90% passing through 50 mesh Differental Pressure 300 mmwc Coal Output from Mill 60.9 t/hr

More

Pulverizers 101: Part I - POWER Magazine

2011.8.1 In essence, the performance of a pulverizer is a delicate balancing act between the HGI, fuel fineness, and throughput. 1. A typical MPS-89 pulverizer found in many coal-fired power plants ...

More

Impact Pulverizer - Pin Mill Pulverizer Latest Price,

Contact Supplier Request a quote. 20 To 425 Hp Three Phase Impact Pulveriser Machine, Model No.: Bimp ₹ 3,24,000/ Piece. Get Quote. 100 Hp Bharath Impact Pulversier, More Than 100 Kg/hr ₹ 3,16,000/ Piece. Get Quote. Impact Pulverizer Machine, 440 V, Capacity: 0.5 To 8 Tph ₹ 4,49,000/ Piece.

More

Coal Pulverizers - an overview ScienceDirect Topics

Steam power plants, components. Masood Ebrahimi, in Power Generation Technologies, 2023. Abstract. In the sixth chapter, the main components and auxiliary systems of the steam power plants (SPP) including the steam turbine, condenser, feedwater pump, steam generator, deaerator, close feedwater heater, superheater, economizer, drum, sealing

More

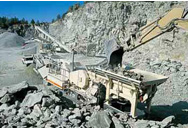

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Crushers, grinding mills and pulverizers are types of grinding equipment used to transform or reduce a coarse material such as stone, coal, or slag into a smaller, finer material. Grinding equipment can be classified into to two basic types, crushers and grinders. Industrial crushers are the first level of size reducer; further granularization ...

More

Pulveriser-Power Plant PDF Furnace Combustion - Scribd

2014.3.3 Pulveriser-power plant ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. use of mechanical engg ... The mill grinding heat dissipation, varies from 20 to 40 kJ/kg of coal. Mill Heat Balance: Energy for Drying of Coal Determine the latent heat per kg of water evaporated.

More

CFD based investigations into optimization of coal pulveriser ...

2009.9.1 In coal-fired power plant, pulveriser is the first major component, whose performance dictates the total power plant efficiency. ... Coal pulverizers or mills grind coal typically from 10–50 mm size coal lumps to provide fine coal dust particles usually less than a micron up to several microns in size (with at least 70% by weight not ...

More

fr/pulveriser mill coal power.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

More

PAPER OPEN ACCESS Program Design and Calculation

In this study, the A mill of NO.1 unit of a power plant is selected as an example. The unit is 350MW supercritical coal-fired heating unit, and the pulverizing system is a positive pressure direct fired pulverizing systems with medium speed mill, and the mill is MPS180HP-II mill, which is made by Changchun generating equipment plant.

More

CFD analysis: bowling for pulverized coal - Power Engineering International

2009.5.1 In a bowl-mill coal pulverizer, raw coal, which is fed through a central coal pipe at the top of coal pulverizer, falls by gravity to a rotating grinding table where it is pulverized between grinding rollers. ... Cui, J. and Munukutla, S., “CFD Application for Coal/Air Balancing in Power Plants” Applied Mathematical Modeling, vol.30, pp ...

More

Pulverizers - Commercial Pulverizers Latest Price,

Contact Supplier Request a quote. Confider Mild Steel 3 Hp Ms 2 In 1 Pulverizer For Commercial,... ₹ 21,000/ Unit. Get Quote. Semi Autometic Stainless Steel Wet And Dry Ss Pulverizer ₹ 41,500/ Piece. Get Quote. 2hp Single Phase Turmeric Grinding Machine For Home Or Turmeric... ₹ 31,500/ Piece. Get Quote. Pulverizers.

More

Ensure clean dry lube oil on coal mill pulveriser, install a

Your solutions. For coal mill pulveriser lube oil the following CJC ® system solutions apply: Coal Mill Filter 1, HDU 27/81. Oil Contamination Monitor, OCM15. The CJC® System solutions fit all coal mill pulveriser systems regardless of oil volume, and we can deliver globally where required. In close co-operation with technical organizations ...

More

(PDF) Fault analysis and optimization technology of HP

2021.8.1 Ismail Syed. Mihir Sarangi. Parida Aditya. Uday Kumar. A root cause failure analysis of coal mill vertical shaft used in thermal power plant has been carried out. The failed parts of the shaft ...

More

TECHNICAL SPECIFICATION OF WET BALL MILL

2023.7.14 TECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT (SUB ASSEMBLY OF FGD SYSTEM) ... REV DATE PREPARED CHECKED APPROVED Bharat Heavy Electricals Limited Heavy Power Equipment Plant Ramachandrapuram, Hyderabad - 502032 SPECIFICATION No.: BA89015 ... Patratu Thermal Power station (PTPS) is

More

PULVERIZE中文(简体)翻译:剑桥词典 - Cambridge Dictionary

PULVERIZE翻译:把(某物)压(或磨)成粉, 轻松打败。。 The ingots are pulverized and milled to tiny particles, which then undergo a process of liquid-phase sintering in which the powder is magnetically aligned into dense blocks.

More

Dynamic Modelling and Simulation of Coal Pulverizer

2021.9.4 The mathematical model and simulation of coal pulverizer has been presented in the paper using first principle mass and heat balance equations based on physical insight. The coal mass flow is modelled based on the mass balance model. The pulverized coal temperature is modelled by considering the coal and the pulverized coal

More