placer gold beneficiation plant

The Anatomy of a Great Placer Gold Wash Plant in

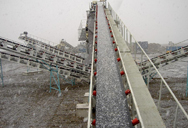

2020.8.28 The placer gold wash plant is located in Xinjiang. Its capacity is 120 TPH. Due to the relatively large proportion of gold (17.50 ~ 18.0), we designed a set of gravity beneficiation solutions for our

More

Placer Gold Mining Process, Equipment - JXSC Machinery

3 天之前 The common methods of placer gold beneficiation include gravity separation, flotation, mercury amalgamation, etc. Application: The alluvial/ placer gold process is

More

An Introduction to Placer Gold Recovery Methods

2020.10.15 The principle of placer gold recovery methods is to use gravity dressing method first. The gravity dressing method can recover the gold and its associated heavy minerals from the raw ore to the greatest

More

THE ANATOMY OF A GREAT PLACER GOLD WASH PLANT IN

2020.10.29 The placer gold wash plant is located in Xinjiang. Its capacity is 120 TPH. Due to the relatively large proportion of gold (17.50 ~ 18.0), we designed a set of gravity

More

Estimation of operating costs and energy consumption

productivity of 70 and 100 m3/h is intended for washing and beneficiation of gold-bearing sands during the development of bouldery placer deposits. Since the beginning of the

More

Very Simple and Efficient Placer Gold Beneficiation Program

The most commonly used methods of placer gold beneficiation are: flotation method, gravity beneficiation method, mercury mixing method, etc. Due to its advantages of low cost, high...

More

Gravity beneficiation process methord for placer alluvial gold

2023.4.10 Gravity separation is a key operation in the beneficiation stage of placer gold mines. Gravity separation equipment such as Centrifugal concentrator, Trommel,

More

Integrated Technology for Processing Gold-Bearing Ore

2021.9.24 The use of gravity beneficiation methods is due to the presence in auriferous ore, along with finely disseminated, free coarse gold, which is not fully

More

Placer gold beneficiation process Prominer

2021.3.22 The beneficiation process of placer gold is mainly used in coastal placer, riverside placer or alluvial placer. The process flow of placer gold beneficiation includes cracking, screening, desliming stage,

More

Placer Gold Ore Beneficiation Equipment and Methods

2020.12.1 The principle of the beneficiation process of placer gold ore is to first use gravity separation to recover gold and its associated heavy minerals from the original ore

More

Bauxite Beneficiation Tailings Reprocessing

2024.1.17 Bauxite flotation process plant. 1. The mined bauxite mixture is screened through a single-layer or multi-layer screen surface by a vibrating screen; 2. Preliminary crushing of the screened aluminum ore

More

Niobium-Tantalum Ore Beneficiation - JXSC Machinery

2024.1.17 The chemical formula of niobium-iron ore-tantalite is AB2O6, both of which are referred to as niobium-tantalum. Where A in the formula stands for iron and manganese, and B stands for niobium and tantalum. The magnetization rate of niobium-iron ore-tantalite is (22.1 to 37.2) × 10-6. The dielectric coefficient of niobium-iron ore is 10 to 12 ...

More

Alluvial and Placer Deposits Wash Plant for Gold Mining

2024.1.11 In view of occurrence of gold in the different raw materials of placer, alluvial / eluvial deposits and allowing for small, medium large scale of processing for mining, prospecting and batch sampling, HZE provides different wash plant combing mercury free processes and related complete sets of equipment, to recover gold with

More

Iron Ore Beneficiation Plant - JXSC Machinery - Mineral

3 天之前 2. The jaw crusher crushes 50-230mm iron ore into the fine jaw crusher. Spiral washing machine is suitable for cleaning 0-50mm materials. 3. The fine jaw crusher crushes the material to 0-20mm. The vibrating screen sends the 0-20mm material into the ball mill, and the +20mm material returns to the fine jaw crusher.

More

How to Extract Gold From Ore? Mining Pedia

2022.2.11 For placer gold beneficiation, the difference in specific gravity is ≥1.25 and the ore monomer under the premise of dissociation, the lower limit particle size can reach 0.04mm. The process operation is simple and the equipment processing capacity is large, which is very effective in processing rough gold ore. ... In vein gold dressing plants ...

More

Treatment And Utilization Of Gold Mine Tailings

2024.1.17 The placer or rocks mined from underground which contains gold is called ore. The gold mining process involves crushing the ore into sand and dust to liberate and recover the gold. What’s leftover is called tailings. Ballarat Gold Mine uses its robust management and monitoring processes to make sure its produced gold tailings comply

More

Zircon Beneficiation Plant - JXSC Mineral

Zircon sand beneficiation is removing impurity minerals from zircon sand ore and increasing the content of zircon sand ore. We determine the beneficiation process and equipment configuration according to the zircon placer’s specific mineral composition and properties. The common zircon sand beneficiation process is a composite beneficiation ...

More

Tin Ore Beneficiation Methods And Some Practice

2024.1.17 The gravity separation method is generally used for sand tin ore. The process of gravity separation of tin sand ore usually adopts multi-stage grinding and multi-stage separation process. Those processing can make tin ores dissociation and get recovered in the early stage processing and also remove some tailing to avoid uneven

More

Gold Processing Plant, Equipment - JXSC Machinery

2 天之前 Gold ore processing plants are common including washing screening, crushing grinding, beneficiation, concentrating, drying or smelting. 1. Washing screening: It is mainly to remove the mud in the placer gold ore, or to make the particle size meet the requirements of the sorting operation. 2. Crushing grinding: The content of gold in the ...

More

Gold Processing Equipment, Process Flow, Cases - JXSC Machine

2019.8.22 The gold-silver-containing liquid is carbon-adsorbed with activated carbon and then desorbed to recover gold and silver. Placer gold wash plant. Placer gold process. The gold content in the placer gold mine is extremely low, and it is known as the gold panning by beneficiate the placer gold through various energy-efficient placer gold

More

Introduction to Mineral Processing or

2018.1.12 The first rule deals with the conservation of mass. The total flow of the material into the process plant equals the total flow out. The second rule relates to the quality or grade of the concentrate product. In

More

Mining Mineral Processing Plant - JXSC Machinery

2024.1.23 Precious metals minerals processing plant refers to gold, silver, diamond and platinum group metals, especially the gold mining and peocessing plant inclding flotation and gravity separation, CIL, CIP process, etc. We are ore processing plant and equipment supplier from China, with over 35 years of rich experience in beneficiation, support

More

Overview of Ore Washing in the Mineral

2021.2.17 It is often used for difficult-to-wash ores and has a strong scrubbing effect. Pre-soak the ore, set high-pressure water spray during the washing process, apply vibration, add a small amount of ...

More

Collection Of Alluvial And Rock Gold Beneficiation Methods

2024.1.11 Crushing and Grinding: Rock gold is often embedded in hard rock, and the rock first needs to be ground and broken to release the gold ore. Gravity separation: Similar to placer gold, rock gold can also be initially separated by gravity separation. This can be achieved using vibration tables, centrifuges, spiral chutes and other equipment. Flotation:

More

Ilmenite: An Ore of Titanium Beneficiation and Plant

2023.10.27 It can reduce unnecessary investment in equipment to obtain ideal beneficiation results. Ilmenite is a black iron-titanium oxide (FeTiO 3) with the main mineral components of hematite, magnetite, pyrite, pyroxene, and amphibole. Ilmenite in placer deposits often contains a large amount of slime. Ilmenite mineral's Mohs scale hardness

More

Existing and New Processes for Beneficiation of Indian Iron

2020.2.8 Cliff’s Tilden plant in Cleveland, USA, is the only iron ore beneficiation plant, where selective flocculation technique, using degraded starch as the flocculant, has been applied to produce pellet grade concentrate from a feed containing around 32% Fe . The plant has a capacity of processing 10 million tons and is in operation since 1975.

More

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023.5.27 Shaking table, also called gold recovery table or gold separation table, is the best fine gold recovery equipment. It can process both gold ore in quartz rock, gold stones, and placer gold. The feeding particle size range of the shaking table is generally between 3mm-0.019mm. The gold beneficiation is stable and reliable, and the distribution ...

More

Copper Ore Processing Plants, Flow And Equipment

2024.1.17 Copper industrial minerals include: natural copper, chalcopyrite, chalcocite, tetrahedrite, azurite, malachite, etc. Chalcopyrite (a compound of copper, sulfur, and iron) is mined mainly, followed by chalcocite and bornite. If copper ore wants to be fully utilized, it must be processed by flotation. Flotation separation is an important copper ore

More

Breakthrough In High Grade Rutile Beneficiation Method

2024.1.11 About Rutile Ore. Rutile is one of the main minerals containing titanium. It is brittle, with a hardness of 6-6.5 and a density of 4.2-4.3g/cm3. Those rich in iron, niobium, and tantalum will increase in density, and the higher ones can reach more than 5.5g/cm3. It can be dissolved in hot phosphoric acid.

More

Research and application of a Knelson concentrator: A review

2020.6.15 The Knelson concentrator (KC) is widely used in gold ore and other precious metal ore processing technology because of its excellent separation performance. The development history and types of KCs are reviewed in this paper. Research on the separation mechanism and characteristics of KCs was analyzed and discussed, including

More

Progress of Five Spodumene Beneficiation Methods

2024.1.17 1. Hand Separation method. In the 1950s and 1960s, manual beneficiation was one of the main beneficiation methods in the production of lithium concentrate and beryl concentrate at home and abroad. For example, in 1959, the hand-selected beryl concentrate in Xinjiang, Hunan and other provinces and regions in my country reached more than

More

How to Get Gold From Alluvial/Placer Gold Ore

2015.12.3 Alluvial Gold Separator The gold content is low in alluvial/placer gold ore and kind of high efficiency and energy-saving beneficiation equipment is needed to get ideal concentrating efficiency.

More

Integrated Technology for Processing Gold-Bearing Ore

2021.9.24 Primary auriferous ores in terms of their mineral composition and textural and structural characteristics belong to the category of refractory mineral raw materials [1, 2].The extraction of gold from these ores is of particular importance for all gold-mining and processing countries in the world [], since the reserves of placer gold are depleted,

More

what are the placer gold mining methods? - Mining-pedia

2021.3.11 1. Gold dredger mining method. The dredger mining method of placer gold is to mine placer gold in the river by means of the dredger. Due to its simple operation, high work efficiency, and high benefit, the gold dredger is widely used. Process flow: first use the digging bucket of the gold dredger to do placer gold mining, and feed the mined ...

More

Alluvial Gold Beneficiation Method: It's Not As Difficult As

2020.10.26 alluvial gold wash plant case. Principle of gold ore beneficiation: first use gravity beneficiation method to recover gold and all kinds of associated heavy minerals from the original ore to the maximum extent. The gold and various heavy minerals are then separated from each other by a combination of gravity beneficiation, flotation, mercury ...

More

An Introduction to Placer Gold Recovery Methods

2020.10.15 1. Using gold pan to wash gold grains and discard heavy sand. 2. Use a mercury mixing cylinder to mix mercury inside, and discard the heavy sand after obtaining the amalgam. 3. After artificial panning or amalgamation to extract gold, heavy sand shall be sent to concentrate plant for beneficiation.

More

The Processing of Copper Ore Beneficiation - JXSC Machinery

2024.1.11 The copper ore beneficiation plant uses three processes: crushing, grinding and beneficiation. It’s just that the selection of individual copper ore processing equipment and beneficiation technology will be slightly different. Among them, in the crushing process, the use of three-stage closed-circuit crushing can well complete the

More

Lithium Processing Plant, Equipment - JXSC Machinery

2 天之前 Lithium beneficiation processing plant includes crushing, grinding, gravity separation, flotation, magnetic separation and combined process. According to the nature of lithium ore (spodumene, lepidolite, lithium feldspar), JXSC supports custom lithium processing plants and equipment to obtain the best separation index. Inquiry Now.

More

Mineral Processing Equipment For Sale - JXSC Machinery

1 天前 We are a professional manufacturer of high-quality beneficiation equipment covering gold, diamond, copper, manganese, tin, lead-zinc, iron, coltan, chrome, silica sand, kaolin and 200+ mineral processing plants machinery. We provides services for extracting, processing, and beneficiation of ores minerals. Over the last few decades, JXSC has ...

More

How To Extract Gold From Sand? - Mining-pedia

2020.4.23 Because the capacity of jig and shaking table is small. 2. Spiral chute roughing, Jig scavenging and shaker concentration. After washing and screening with vibrating screen or trommel screen, the combined process of spiral chute roughing-jig scavenging -shaking table concentration is used to extract gold from sand.

More